Categories

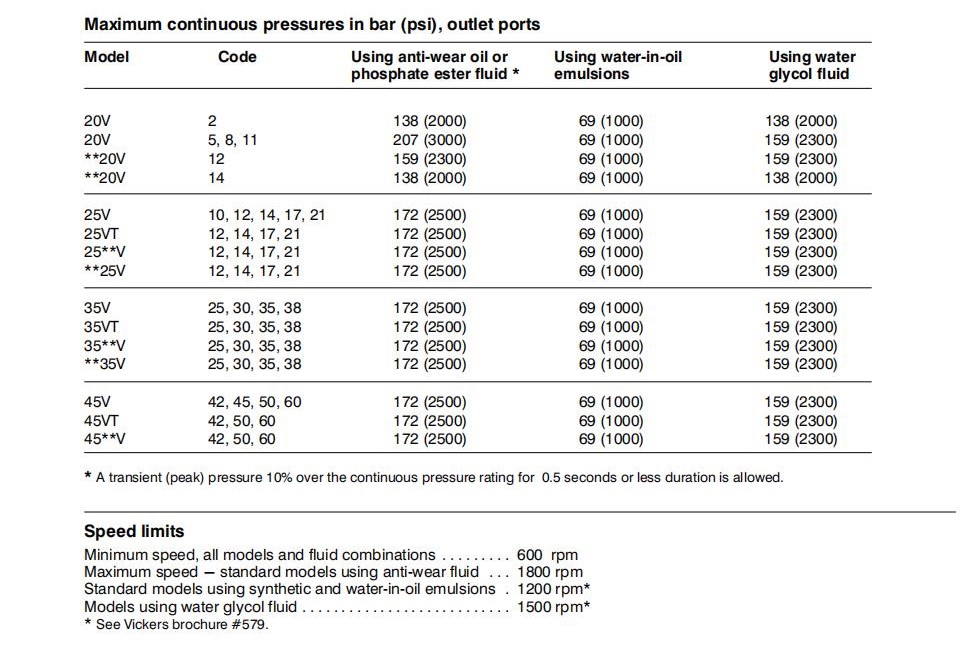

-High working pressure capability in a compact form factor High working pressure capability in a compact form factor, ensuring a high power-to-weight ratio and low installation costs

-The inherent low noise characteristics of the sub-blade mechanism improve the operating operator comfort

-12-blade system ensures small amplitude of flow pulsation and system noise characteristics are low

-Designed to prevent internally induced radial loads on shafts and bearings Hydraulic balancing ensures long life

-By eliminating dual shaft extension motors or by reducing the number of motors and number of drive couplings, duplex pumps and through-shaft drive configurations Save installation locations and costs

-Through-axis drive models offer valuable circuit design flexibility, such as such as quantitative and variable types on a single input drive

-16 flow displacements and the ability to achieve high working pressures provide you with the best choice for the entire range of flow and pressure requirements and single-source capability

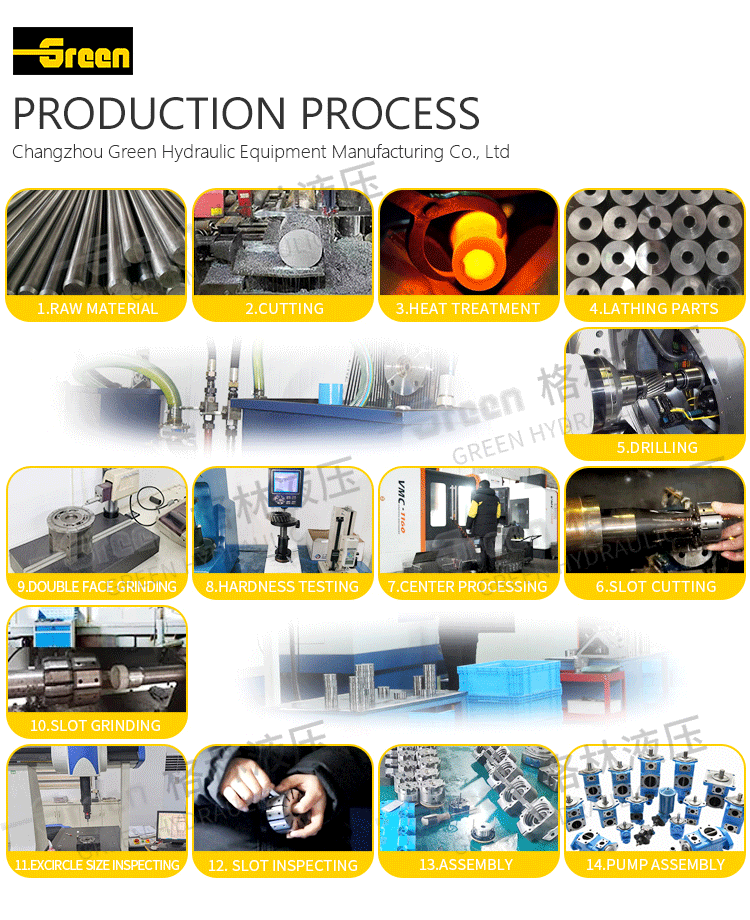

-Factory-tested movement kit installed to provide new pump performance

-The movement kit construction ensures quick and efficient field repair The The movement is separate from the drive shaft, so the pump can be easily changed and serviced without folding the pump from its The flow capacity can be easily changed and serviced without folding the pump from its seat.

-The oil inlet and outlet ports can be oriented in four different positions to each other relative to each other, providing great installation flexibility and facilitating machine design

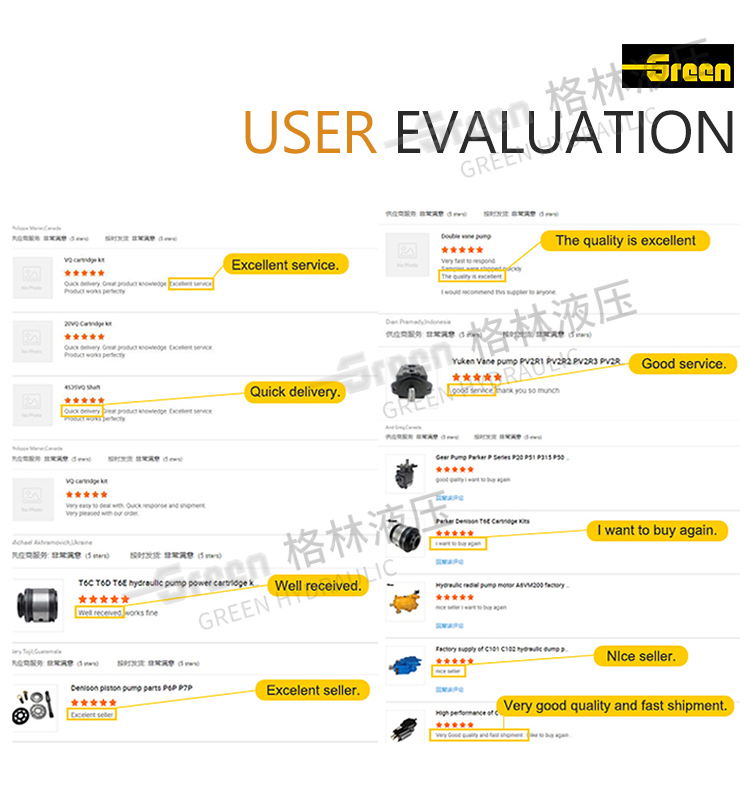

To pursuit of the perfect quality of products, To pursuit of the best price of the products, To make sure of the service is satisfactory to every customer.

E-mail: Emily@gelinyy.com

Mobile: 008613685276555

Tel: 008613685276555

WhatsApp: +86-13685276555

Add: No.38xueyeroad,Xinbei,Changzhou,Jiangsu